Original article by H’Rina DeTroy from NC State University News

Achieving Biomimicry in 3D-printed Tissues

Elsewhere in the College of Engineering, researchers have developed a way to use ultrasound to improve 3D-printed tissue’s ability to mimic and function like natural, organic tissue.

Current technologies can create medical products like knee implants by printing living cells. However, one of bioprinting’s major challenges has been effectively organizing these cells so that the engineered tissue achieves biomimicry, or in other words, imitates organic tissue’s biological structure and functioning.

Rohan Shirwaiker, the James T. Ryan professor in NC State’s Edward P. Fitts Department of Industrial and Systems Engineering, is leading a team that aims to tackle that challenge. They’re innovating the bioprinting process by using ultrasound waves to organize the cellular structures in printed tissues so that they more closely resemble — in form and function — the real, organic thing.

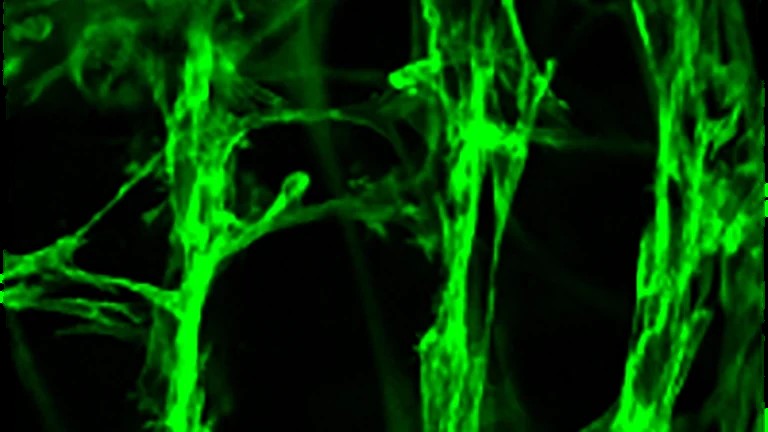

“Through this ultrasound-assisted biofabrication process, we are studying how in conjunction with 3D printing, we can use ultrasound waves to organize cells and collagen and other fibers to mimic the organization of natural tissues,” Shirwaiker said.

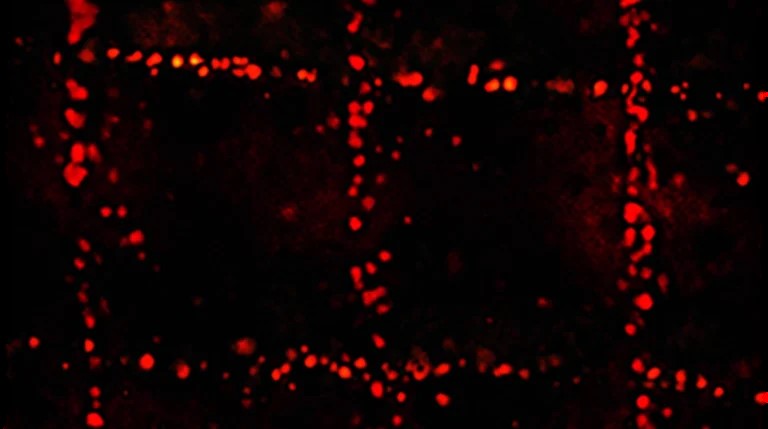

Cells, collagen and fibers naturally grow in certain patterns so they can carry out their biological functions. The research team is seeking ways to mimic these natural patterns in biofabricated tissues so that they can carry out the same functions.

“The ultrasound waves — the vibrations — are pushing the cells into patterns,” Shirwaiker said. “[The technology] is able to organize single cells and fibers into a pattern that we want to make tissues that are functional — mechanically and biologically — inside the body.”

To achieve the desired pattern, the researchers built specialized ultrasound chambers that direct ultrasonic waves across the area where living cells are printed. The soundwaves travel in one direction and then bounce back, guiding the cells into rows and aligning them at the points where the waves intersect with their reflections. The technique has been proven effective in organizing the cells into a 3D matrix that resembles a natural tissue’s structure.

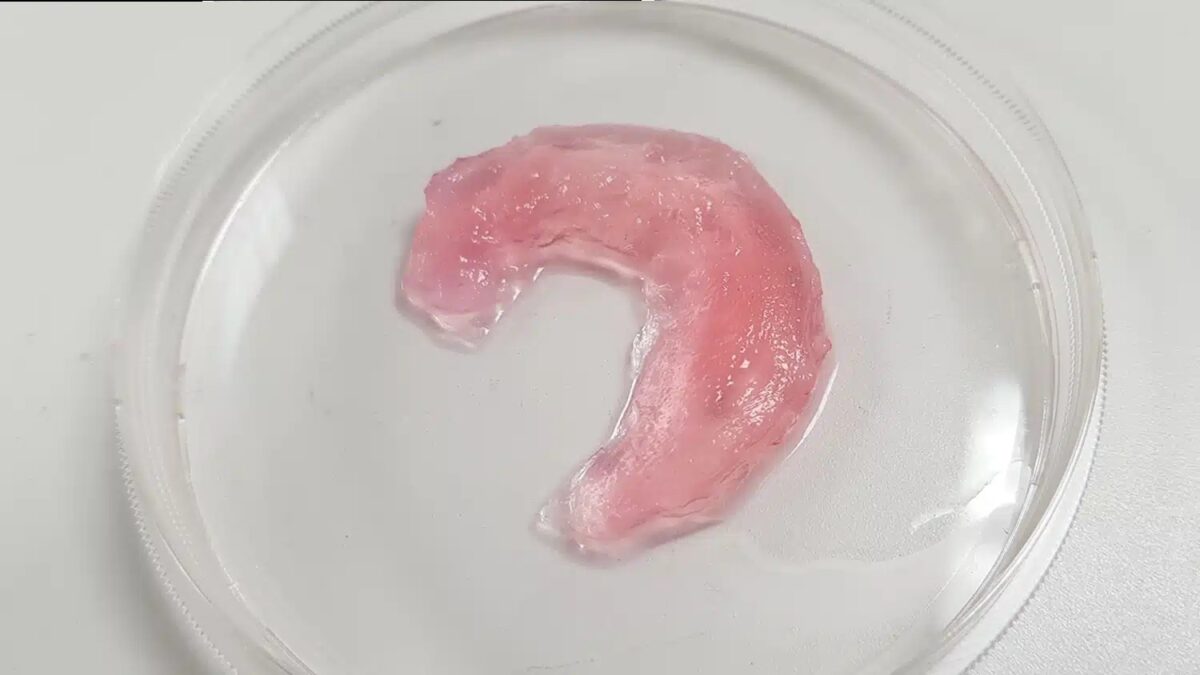

Shirwaiker’s team has successfully printed a knee meniscus — one of the trickiest types of tissue to print — that closely mirrors its organic structure. Since the knee joint must bear significant weight, engineering artificial tissue accurately for it is especially crucial.

“The knee meniscus has a very unique organization and a biomechanical function in the body,” Shirwaiker said. “When we walk, run and perform other routine activities, that tissue has to absorb a lot of the load and support our ambulatory functions.”

“Our [ultrasound-assisted biofabrication] process is one of the very few that can create the three-dimensional organization in a very organically shaped new meniscus.”

Shirwaiker said that he and his team have a patent pending for their ultrasound-assisted process.

Safe and Affordable: Ultrasound Evolves

For Shirwaiker, Jiang and Muller, one of the biggest advantages of ultrasound is that it doesn’t cost much to manufacture. Looking toward the future, the affordability of ultrasound technology paired with machine learning and AI will push innovations even further.

Portable and wearable ultrasound devices that use machine learning are being created for the not-too-distant future. Such devices would support machine learning and could use the QUS parameters Muller’s team developed. These ultrasound-based health aids would be useful for chronic disease, allowing patients ongoing and immediate monitoring without requiring a trip to a medical facility.

“The time is ripe right now with the advances in the hardware,” Muller said. ”It’s amazing what people can do right now with stretchable, stickable, even implantable or swallowable ultrasound devices. Combine that with quantitative ultrasound and machine learning, and you have a completely integrated intelligence system that people can take home.”

Muller believes innovations in ultrasound coupled with advances in hardware have the potential to help millions of people.

“So many people don’t have access to healthcare, so it matters a lot to me,” Muller said. “I see it as an empowerment tool for people to take care of their own health.”

In the meantime, the research continues. It seems apt that Muller, Jiang, Shirwaiker and their research teams are leveraging how sound waves pass through objects and beyond boundaries. Likewise, the innovative potential of ultrasound and these dedicated scientists at NC State are limitless.

Read the full article for more information on NC State’s innovations in ultrasounds.