Past Senior Design Projects | 2019 | NC State ISE

Past Senior Design Projects | 2019

Each semester we have the pleasure of working with local companies on projects as part of our Senior Design Program. These projects are an opportunity for companies to use student resources to have new concepts and fresh ideas injected into their real-world projects. This sponsorship is rewarding for both the project sponsor and the student team. We would like to thank all our past sponsors for their participation in the program.

Fall 2019 | Photo Gallery

ABB

Student Team: Jacob Green, Rebecca Griffin, Matthew Parker, John Schell

ABB is a world-class leader in power systems products. The senior design team created a user-interface application that allows users to search for previous successful projects. Once a user inputs search criteria, the application will return the data of past successful projects with similar search characteristics. The user can view costs (supplies, labor, etc.) to gauge pricing for a new project.

Carolina Country Snacks

Student Team: Kevin Church, Jasmine Cooper, Ashton Daniel, Zack Hoeksel

Carolina Country Snacks produces pork skin snacks and a variety of other snack foods. They wanted to improve throughput and optimize bagging operations. The student team gathered shop-floor data to create production standards. They also identified bottlenecks within the production processes, increased bags per minute and cut changeover times.

GSK

Student Team: Claudia Alvarado Espino, Yash Mathradas, Alberto Sucre, Samantha Winterrowd

GSK, a global pharmaceutical manufacturer, wanted to increase the throughput of their metered dose inhalers (MDI) product line. The student team analyzed the packaging process and investigated inefficiencies. The student team made recommendations on machine speeds and operator placement to increase throughput by least 3% while maintaining product quality. A SIMIO simulation model of the packaging line was developed and used to confirm their results.

NC State Sports Medicine

Student Team: Steven Lepore, Samuel Stump, Conner Walker

NC State Sports Medicine serves the entire University’s athletics organization. The staff wanted to improve the current manual sign-in processes that include binders of forms and data and no standardization across teams. The senior design team analyzed the entire process and developed an App to streamline the sign-in process. They improved data collection methods and provided a means to share information about an athlete’s rehabilitation.

Patch Rubber Company

Student Team: Pedro Fernandez, Julia Hansen, David Newkirk

Patch Rubber is one of the world’s leading manufacturers of traffic marking tapes. They are expanding into the patterned traffic marking tape market. The student team analyzed product changeovers and current tape processing methods and recommended new SOPs, technologies, and solutions. This allowed for not only a smooth introduction of Patch Rubber’s new product but decreased product changeover times by at least 20%.

Note in the Pocket

Student Team: Alexander Balabanov, Matthew Nega, Samuel Young

Note in the Pocket is a non-profit organization that serves Wake County to provide clothing for students in need. They are looking to double their current capacity while serving more children with greater efficiency. The student team established periodic goals for the organization to determine if growth is being met, while also recommending process improvements.

Novozymes

Student Team: Ethan Miller, Nicole Niemer, Trent Ploeger

Novozymes is a world-wide producer of commercial enzymes for the food, beverage and household care industries. Unique processing equipment requires expensive maintenance parts that are challenging to source. The team studied additive manufacturing methods to reduce the cost of inventories. The senior design team analyzed the different parts to see which can be 3D-printed. They also looked at alternative manufacturing solutions in case additive manufacturing was not cost-effective.

Spring 2019 | Photo Gallery

Century Furniture

Student Team: Juan Arias, Lisa Grossman, Zachary Johnston

Century Furniture has used the same method for setting fabric waste factors for the last 35 years. These factors play a critical part in determining how much fabric they purchase. The student team’s goal is to discover if there is a more accurate method for determining waste factors and improving inventory accuracy, costing of fabric grades, and customer satisfaction.

CVG – Concord

Student Team: Victoria Atkins, Brycen Moser, Zoltan Pukanecz

CVG’s Concord facility produces custom-designed products using three types of plastic manufacturing technologies: injection molding, reaction injection molding, and thermoforming. Up until now, they have used an Excel spreadsheet for their injection molding production schedule. The student team’s mission is to develop an automated system that combines their order data from several sources with their equipment availability to streamline their production scheduling process.

CVG – Concord

Student Team: Joshua Espinoza, Sarah Hartzog, Alexander Janus

CVG’s Concord facility produces custom-designed products using three types of plastic manufacturing technologies: injection molding, reaction injection molding, and thermoforming. As demand has grown, corrugated materials have been stored in random locations this leads to big inefficiencies in the production processes. The student team’s goal is to discover the best way to store these materials to optimize their retrieval and replenishment.

CVG – Kings Mountain

Student Team: Wesley Jones, Carl Johnson, Sarah Troxell

Workers at CVG’s Kings Mountain facility apply a sealer to clean water out of the joints of Mack Truck cabs manually. This can cause inconsistent amounts of sealer in the drip rail as well as missing areas altogether. The student team’s job is to create processes to reduce defects before they reach final inspection, therefore, reducing the number of customer complaints. Finally, having these upgrades pay for themselves in the first year.

Duke Energy

Student Team: Gustavo Darquea, Joanna Fletcher, Matthew Halsted, Jacob Nagy

Duke Energy has several call centers that answer millions of calls from their customers many of which are routine transactions. There are often inconsistencies among these transactions. Duke Energy wants to provide a consistent experience for their customers while at the same time improve the productivity and efficiency of their customer service representatives. The student team’s goal is to develop processes that will reduce the average handle time the routine transactions and predict how these processes will improve customer satisfaction.

GSK

Student Team: Madelyn Lammert, Gibson Russell, LaurieBeth Shapiro, Benjamin Talbert

GSK wants to scale up the production of its multi-dose dry powder inhaler line that treat respiratory conditions like asthma and COPD. They want to make sure they maximize the use of the space in their facility. The student team’s job is to create a simulation model that can be used to figure out what is the best use of its facilities, product mix, and staffing.

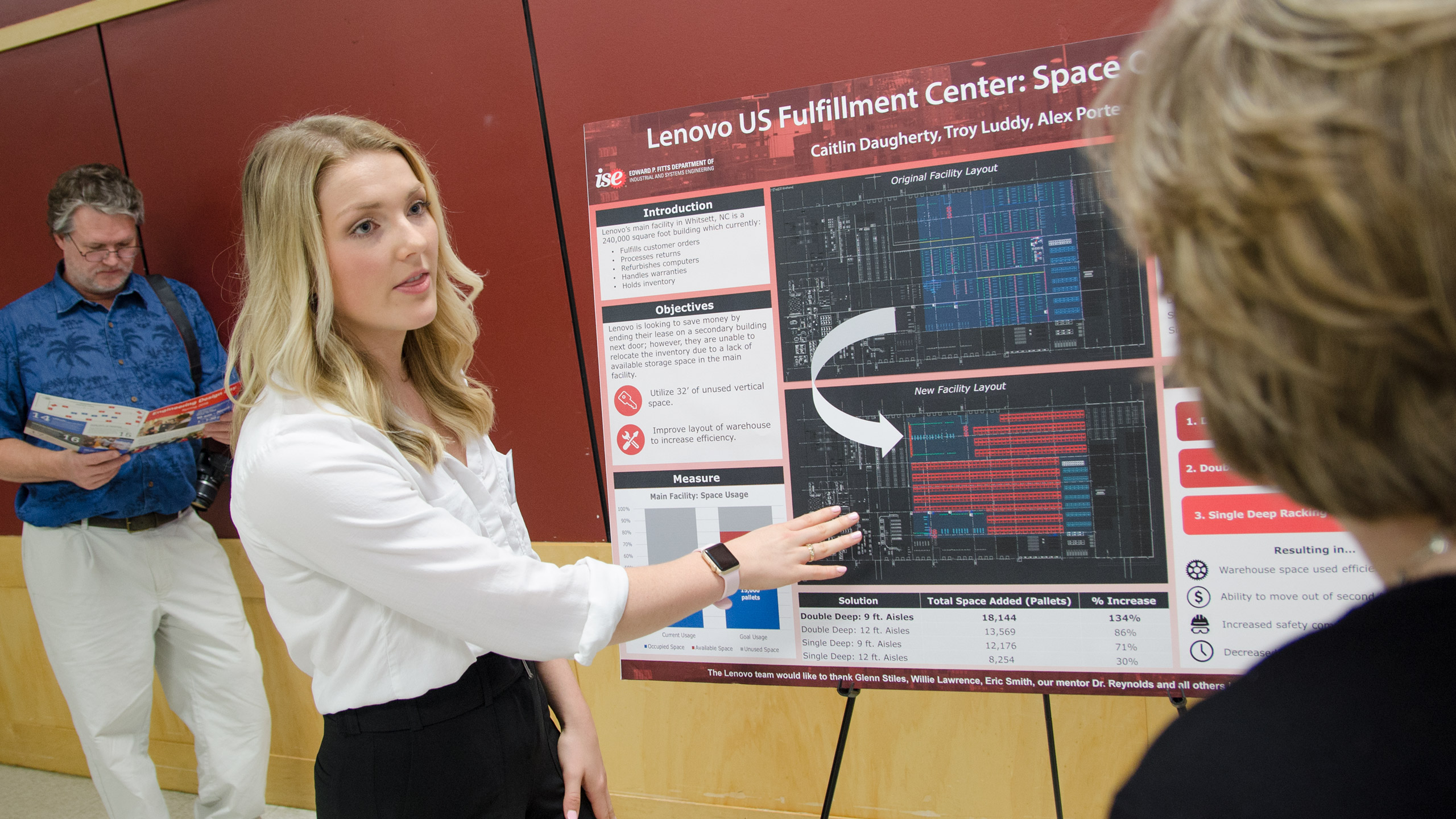

Lenovo

Student Team: Caitlin Daugherty, Troy Luddy, Alexandra Porter

Due to limited space and substantial growth at their US Fulfillment Center, Lenovo is running out of room to store inventory and wants to avoid having to purchase another facility. The student team’s goal is to develop new methods for optimizing storage space and automating the material handling processes.

Red Hat

Student Team: Anton Ipsen, Nishant Singh, Stewart Spanbauer

Driving product awareness and interest is a critical factor of success for any business. Red Hat wants to research ways to optimize the traditional methods of Demand Generation and measure how much awareness they create. The student team’s goal is to discover the effectiveness of “Blitz” Campaigns, such as mass cold-calling, and offer recommendations on whether they should continue with this campaign compared to lead generation.

Secmation

Student Team: Brian Chen, Rachel Hicks, Jackson Hudson, Kyle Rogers

The chemical manufacturing industry must take great care in handling and storing the chemicals they produce. Secmation wanted to develop an Unmanned Ground Vehicle system for use in the Leak Detection and Repair (LDAR) process to increase safety and cut environmental impact. The student team’s job is to define the LDAR tasks and methods for performing those tasks. These tasks will then be used to figure out the requirements for robot mobility, manipulation, and sensing capabilities needed. We will also build a draft proposal to obtain funding for our robotic LDAR concept.

SynTec

Student Team: Madeline Caringi, Alexis Jones, Nicola Sink

Due to limited space, there is a production line balancing issue at SynTec. The small order sizes and small space for storage mean that orders have to be placed on the same pallet, requiring workers to move the parts for newer orders to reach older ones. The student team’s job is to develop a solution that will eliminate the need to stack orders without reducing the output possible.

SynTec

Student Team: Sean Murray, John Poff, Elizabeth Underkoffler

To better gauge whether or not new employees are effectively learning during training, SynTec wants to create learning curves to better understand employee learning. The student team’s goal is to develop learning curves for every operation in our area.

The Medicine Shoppe

Student Team: Adelyn Ballard, Hannah Caison, Madison Huckabee, Macie Ware

Medication non-adherence is a serious problem in the US. The Medicine Shoppe is helping address this problem by expanding the number of pills in a pre-made pack. However, problems related to delivery and inventory have occurred as the program grows. The student team needs to determine how many seniors live in a predetermined zone and define the time period of the insurance agencies. This will allow cash flow to be mapped out and controlled.

Wright Global Graphics

Student Team: Joseph Scott, Matthew Simpson, Austin Soell

Due to the desire to downsize, Wright Global Logistics would like to condense its number of facilities to two. The student team’s job is to analyze the footprint of Wright Global Logistics and make recommendations on how to optimize their space. The goal is to reduce the number of buildings used by one.